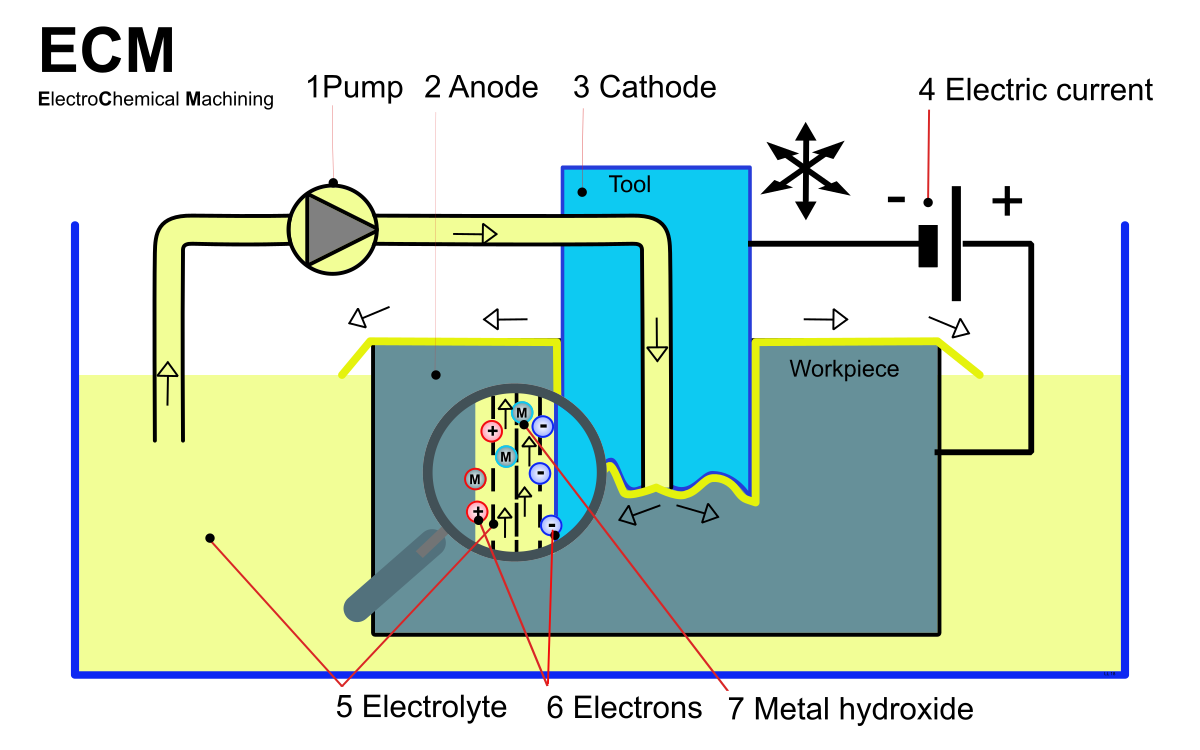

Techniques such as edm and ultrasonic machining offer the ability to machine intricate profiles using a shaped tool but with a relatively low material removal rate.

Abrasive water jet machining wikipedia.

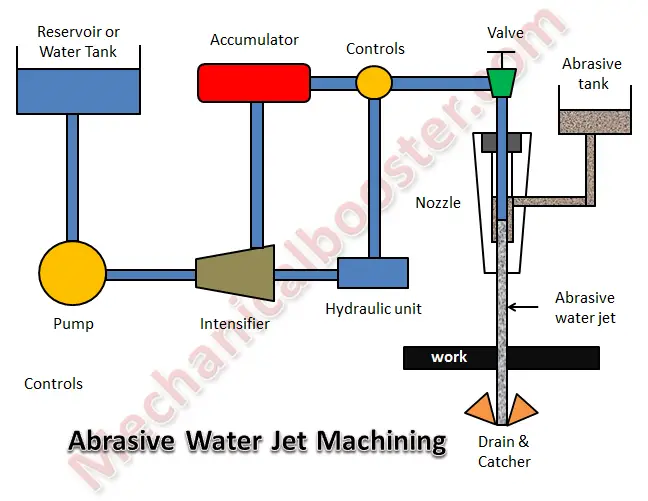

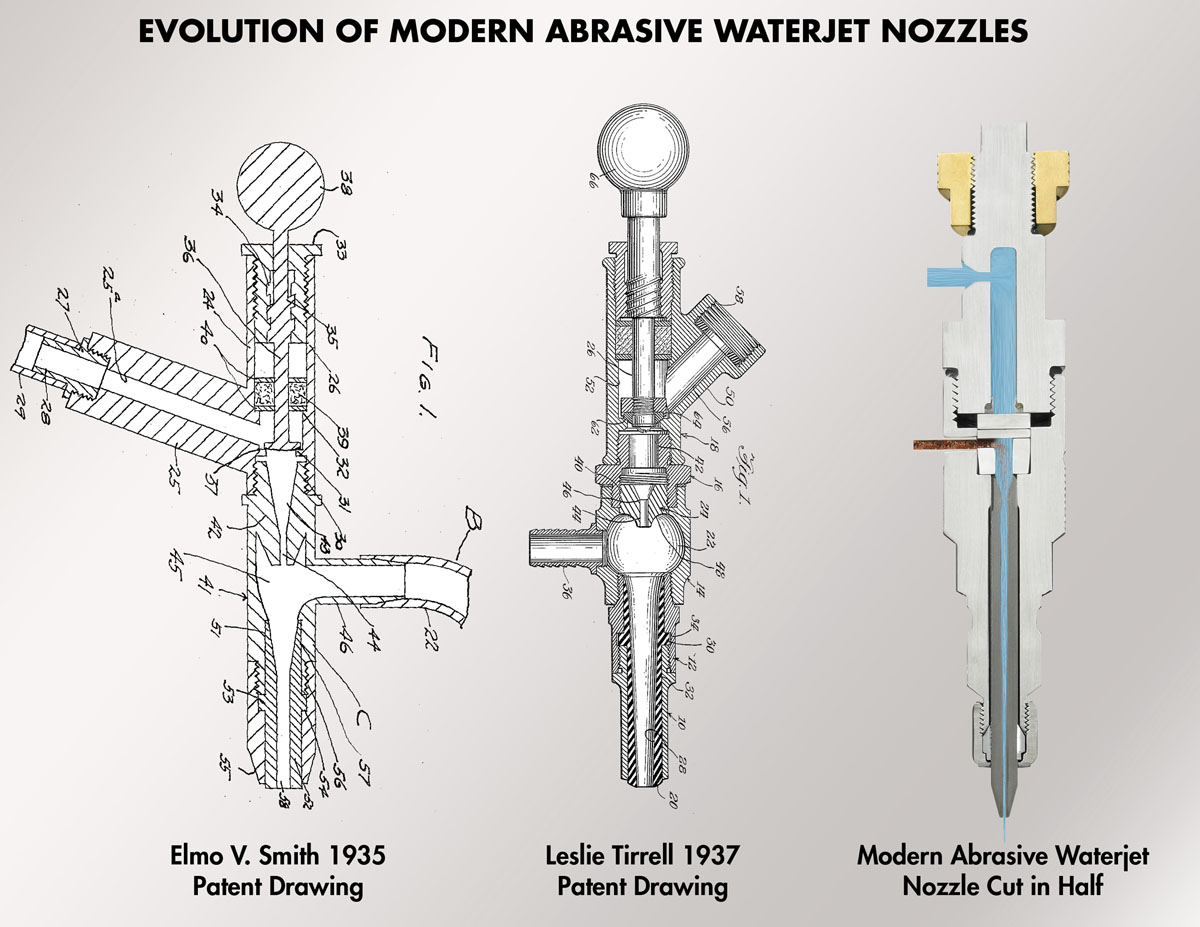

The term abrasive jet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal or granite while the terms pure waterjet and water only cutting refer to waterjet cutting without the use of added abrasives often used for softer materials such as wood or rubber.

Abrasive machining is a machining process where material is removed from a workpiece using a multitude of small abrasive particles.

Principle of water jet machine this process works on the basic principle of water erosion.

The abrasive jet machining is the process of impinging the high speed stream of abrasive particles by high pressure gas or air on the work surface through a nozzle and metal removal occurs due to erosion caused by high speed abrasive particles.

Common uses include cutting heat sensitive brittle thin or hard materials.

Generally the area to be blasted is from about 1 mm 2 to only a few cm 2 at most.

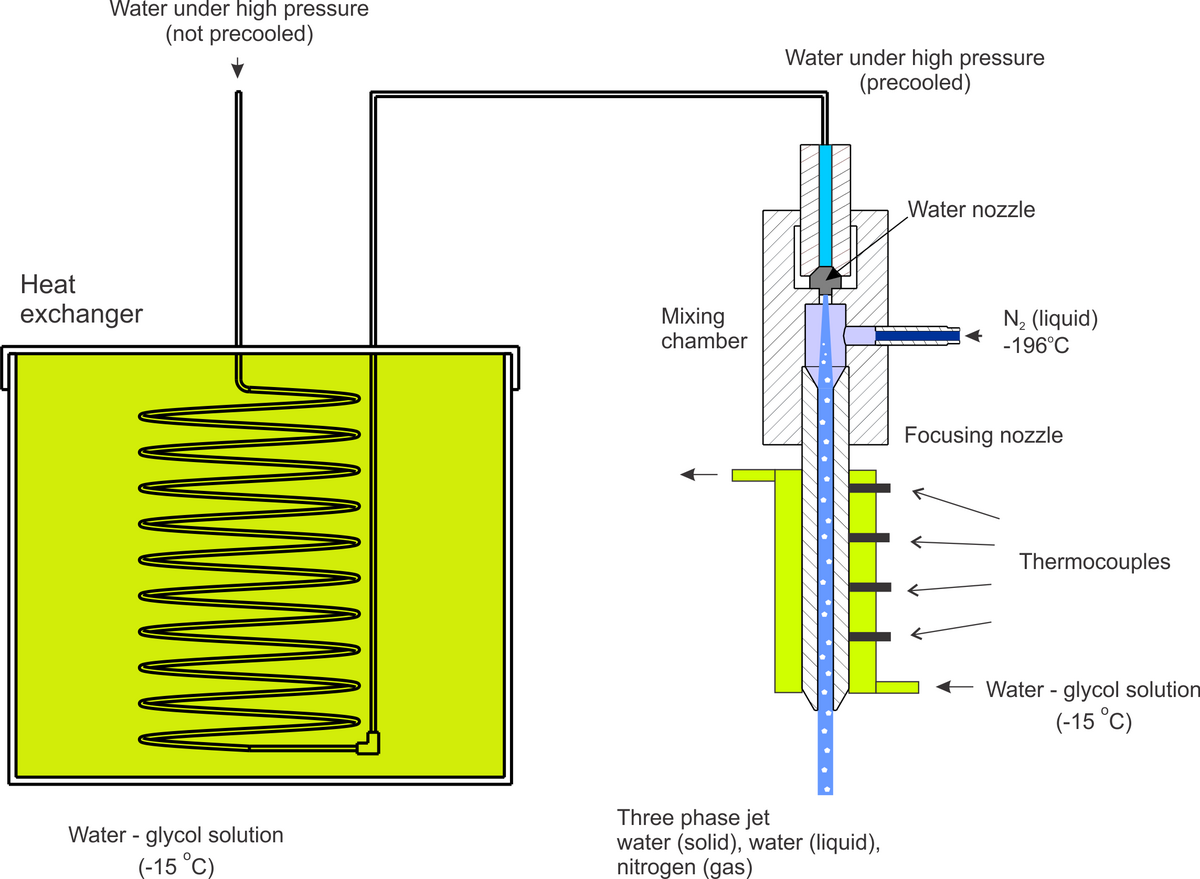

Cryojet icejet is a derivative of the machining process called abrasive waterjet awj machining.

Abrasive jet machining ajm also known as abrasive micro blasting pencil blasting and micro abrasive blasting is an abrasive blasting machining process that uses abrasives propelled by a high velocity gas to erode material from the workpiece.

Abrasive jet machining micro abrasive blasting is dry abrasive blasting process that uses small nozzles typically 0 25 mm to 1 5 mm diameter to deliver a fine stream of abrasive accurately to a small part or a small area on a larger part.

It is ideal process for laser reflective materials where laser beam machining cannot be used.

For machining soft materials water jet machining is used and for machining hard materials abrasive water jet machining is used.

Cryojet icejet technology uses ice particles made of water coming from a running water or freshwater system to cut material.

Noncontact zero tool wear machining processes such as laser and abrasive water jet machining offer potentially reduced costs over conventional diamond grinding.

It does not generate any environmental hazards.

In this process a high speed well concentrated water jet is used to cut the metal it uses the kinetic energy of water particle to erode metal at the contact surface the jet speed is almost 600 m s.

While the ice particles are cutting material they melt and go into the water tank of the machine.